The following is install editorial written by Keith Ball of Bikernet.

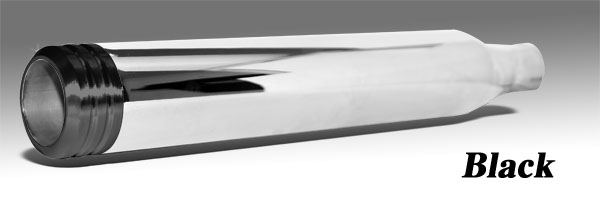

We started the Bassani project of replacing the heavy stock dual catalytic converter system with a light, all black Bassani, FLH-637B two-into-one system.

We started by removing the rear muffler fasteners to the bag bracket.

“Congratulations on owning a genuine set of Bassani exhaust pipes. Bassani pipes are designed for maximum sound and performance,” the supplied literature explained. “Please follow the instructions below for installation. If you have any questions, please call our tech line at 714-630-1821. Thank you!”

Only a simple batch of hand tools was required to complete the job, including:

5/16 hand nut driver

Snap-ring pliers

3/8-inch ratchet and extension

3/8-inch socket swivel

½ and 9/16-inch short sockets

Flathead screwdriver

3/8 inch Allen socket with ¼ hex socket driver

There’s only a couple of clamps, one on the front of the transmission, and one under the bike in the center for the cross-over line.

We also needed a couple more hand tools and some blue Loctite, but it was all minor. First, we removed the saddlebags and set them aside. Then, starting at the rear of the bike, we began taking off the stock system, first with the ½-inch muffler fasteners under the bags, then the muffler clamps, and the crossover clamp under the bike. Then we undid the transmission mount and removed the right floorboard, which was a much easier operation on this new frame. Next, we used the swivel and the short ½-inch socket to remove the exhaust header flanges and we were ready to pop the system free.

The 02 sensors were tight as hell, so I sprayed them carefully with Yield, a bolt removal chemical, and let them set for 15 minutes. They are held on with a 7/8-inch open-end wrench, a rare puppy. Bassani shipped the exhaust and the heat shields separately, with separate instructions, which twisted our minds a couple of times, but all the elements were there, including:

Transmission bracket

Flange nut and bolt

1 7/8 P clamp for the transmission

2-1 7/8-inch band clamps for the header to the muffler connection and seal

And a batch of heat shield stainless clamps

My rare 7/8 open end wrench. The key is to unplug the sensors from the wiring loom, so we could move the pipes away from the bike for a better grip.

A complete system of full-coverage heat shields was supplied. Heat shields nowadays are predominately blue chrome shields for chromed systems. In this case, the black heat shields could have been reduced substantially, so we used some and set some aside.

Here’s an exhaust flange, notice the indent for the circlip.

Fasteners, gaskets, and exhaust flanges are an odd mix with most custom exhaust systems. If you are building a bike from scratch, you will generally need the exhaust flanges, spun gaskets, and sprung clip rings. Plus, we generally need some fasteners.

I generally like to replace the factory exhaust port, steel wool gaskets, but they’re funny. Bassani recommended that we check and replace if damaged. More and more, I agree. If they look good and solid, not burnt or dinged, leave them alone. Sometimes replacing them is a pain and the new one gets jacked around during installation.

This is the new pipe/transmission bracket clamp from Bassani.

In some cases with touring bikes, the pipe manufacturer supplies a new transmission bracket. In this case, we received a new blacked-out clamp that lined up perfectly with the existing tranny case bracket.

Here’s the flange and circlip in place on the new system.

Next, we took the old flanges and circlips off the stock pipes and Jeremiah made sure we kept front flange with the front exhaust. The circlips slipped off the stock pipes easily and we muscled them onto the new Bassani pipes. We made sure the flange was in place first and turned to the correct side with the indent toward the circlip.

“Install the front head pipe but do not tighten completely,” read the instructions. “Slide the ’P‘ clamp onto the pipe with the ’P‘ pointing downward. Thread the supplied ⅜” bolt through the top arm of the clamp, the bracket, the bottom arm of the clamp, the supplied washer and fasten loosely with the supplied flange nut.”

Actually, they shipped us a too-short 5/16 bolt and we used the original stock 3/8-inch carriage bolt and lock nut with blue Loctite. At this point, we did not tighten anything. We installed the rear head pipe, but didn’t tighten it, just snug during this alignment phase.

Muffler clamps were metric. We had to slide them around to the interior, to avoid the heat shields. We made sure we could see the slots on both sides of the clamp, for proper sealing.

The instructions called for spraying lubricant on the header pipes to allow the muffler to slip on, but we didn’t have a problem. We slipped the clamps on first and tried to decide how to position the heads for access. “What about the heat shields?” Jeremiah pointed out.

We repositioned the clamps a couple of times for access and to avoid the heat shields. The bracket under the bag allows some flexibility. We aligned the muffler with the rubber-mounted bracket and installed the short ½-inch head bolts. Then we returned to the engine and rotated our tightening procedure from exhaust port to exhaust port, tightening each nut a couple of turns as a time and watching the stud threads protruding from the nuts. We also used blue Loctite on these.

Blue Loctite on a muffler fastener. Some say you just need a drop. Jeremiah over-did-it here, but the key is clean, oil and grease free fasteners, for Loctite to work.

Once the flanges were tight, we moved along the pipe tightening the clamp fasteners, the clamps, and the muffler bolts.

Once the system was in place and checked, twice, we followed the Bassani Exhaust Care and Maintenance procedures before installing the heat shields. These recommendations are primarily important for chromed systems:

“Clean with a soft cloth and rubbing alcohol or glass cleaner to remove fingerprints, and any residue before starting. Fingerprints or any residue will stain the finish when pipes get hot.

“Clean with a soft cloth and rubbing alcohol or glass cleaner to remove fingerprints, and any residue before starting. Fingerprints or any residue will stain the finish when pipes get hot.

• DO NOT use an abrasive cleaner or coarse cloth on any chrome-plated surface.

• Use glass cleaner and a soft clean cloth to shine and maintain brilliance.

• Cure the finish (chrome or coated) by running the engine at idle/low rpm for 30 seconds to 1 minute. Stop engine and allow pipes to cool. Repeat this step 3-4 times.”

Also, on long system such as this one, it’s a good notion to step back and review the alignment. Once in a while spacers, need to be placed between the mufflers and the bag brackets to align the system with the bike. Next, we carefully installed several heat shields using the supplied clamps.

In each case, we tried to ensure the appropriate shield fit properly and determined how the clamp should face for access. Then we slipped the clamp band through the shield runner and spread it gingerly before pressing the bands over the black-coated pipes. There’s a trick to this to prevent scratching and allow the tang and the fastener to thread properly after the shield is in place. If the tang is bent too much, it’s difficult to thread.

Jeremiah replacing the footboard.

MANUFACTURER’S GUARANTEE

• Bassani provides a warranty on manufacturing defects. Manufacturing defects include material and workmanship. All components are inspected and carefully packaged before shipping.

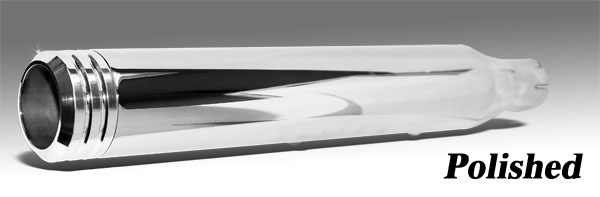

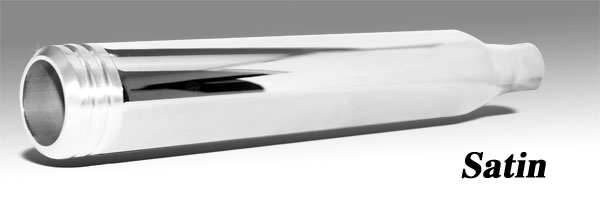

• Chrome plating WILL discolor when exposed to high temperature. * Black pipes are warranted for 90 days from the date of purchase. The high exhaust temperatures found in engines exceed the capabilities of the chrome plating to handle the heat without discoloration. Bassani does not guarantee the pipes against discoloration.

Looks sharp, and he lost a good 30 pounds of non-performing weight.

We fired the bike up, and shut it down before it got too warm. We checked all the fasteners again. Then we took it for a ride. One more check, then Jeremiah rode James’ 2009 off into the Wilmington night. I told him to check it over once more about a week later, in case something comes loose or settles.

Done deal.